// DIY _ CUSTOM _ TAILORED

For your projects, all the best customized professional workmanship click ready.

Our CUSTOMIZATION service is indicated to make your projects and ideas tailored to sound …but not only.

Possibility of material selection, size, processing and quantity on all standards we have (or on individual elements), based on the quoted files sent by you (or by our paid execution) we will evaluate making possibilities and then estimate one or more quotes about cost and timing useful for realization.

Mechanical processing (even on a single piece) through numerical control machines (CNC) and handcrafted finishing, drilling, milling, engraving, bending, folding, punching, digital printing, satin-plating, galvanizing, brushing, assembly with threaded inserts, anodizing, oxidation, etc…

GLAZING and top satin gives high grade finishing and pleasant tactile sense to panels' touch, joint elements and metal inserts. Brushing, shaping and finishing of edges and contours are performed manually by specialized workers.

Through DIGITAL PRINTING lab, we can offer both on our standard and on customized products, a professional silk screen printing service of photo, vector graphic elements or digital drawing. This system does not involve the installation expenses for screen printing frames and allows high definition printing of whole color range allowing the execution for single prototypes or small series of products keeping costs low.

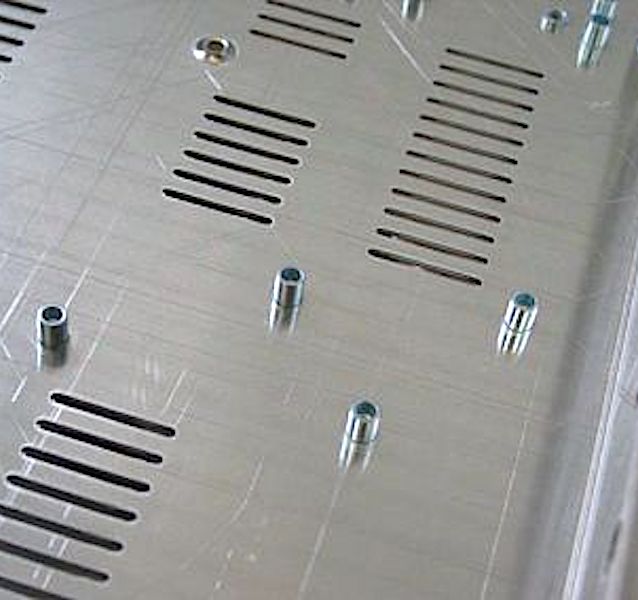

THREADING and threaded inserts are designed for quick and easy installation with the use of a press. They can be mounted on any metal sheet of different thickness. The main advantages are the high torsion resistance and, above all, no damage to surface finishing. Ideal in fixing the printed circuits directly on the case's bottom so that everything is clean and professional ensuring easy and fast assembly.

Standard self-hooking inserts available: spacers (M3x6, M3x8 e M3x10 mm), nuts (M3, M4 e M5) e prisoners (M3x6, M3x8, M3x10, M3x12, M3x15, M4x8 e M4x10 mm).

Standard self-hooking inserts available: spacers (M3x6, M3x8 e M3x10 mm), nuts (M3, M4 e M5) e prisoners (M3x6, M3x8, M3x10, M3x12, M3x15, M4x8 e M4x10 mm).

We're provided of a modern MILLING center with high speed CNC machinery and instrumentation with automatic pallet change that allows us to mill high thickness aluminium panels. The processing of metal sheets is made by professional punching machines with automatic loader for gripping and unloading of foils.

HiFi 2000 di Bettazzoni Gianluca via del Maccabreccia 18 - Lippo di

Calderara - 40012 Bologna (Italy) |

Phone:

051726652

| Email: info@hifi2000.shop

| CF/PI: 03957631207

| © 2022 di HIFI2000. All rights reserved.